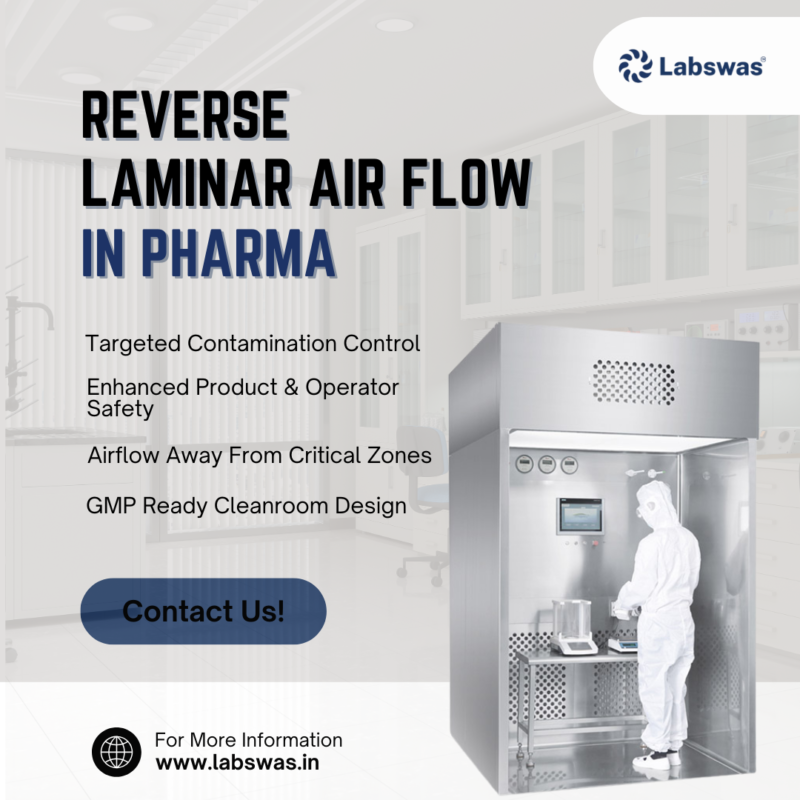

Reverse Laminar Air Flow (RLAF)

Reverse Laminar Air Flow is one of the clean air systems used in laboratories, drug facilities, and hospitals. It has been created to prevent harmful particles, fumes, bacteria, and dust from passing on to the environment. Reverse Laminar Air Flow (RLAF) operates by sucking air in from the front or top and blowing it through filters before discharging it outside. It helps to safeguard individuals and the lab environment from contamination.

RLAF is primarily employed where there is a requirement for handling hazardous materials such as chemicals, powders, or biological specimens. It holds such materials in a particular working area and not in open space, whereby they might injure other people.

Why is Reverse Laminar Air Flow Important?

In places like drug laboratories, people will be working with fine powder or harmful chemicals. Once they are released into the air, these can cause serious health issues. They can also be employed to find other products being manufactured in the same building.

Reverse Laminar Air Flow offers a safe and clean working environment. It captures harmful particles before they are dispersed. This makes the working area dirt-free and also saves the worker who is dealing with the material.

It is also referred to as “reverse” because rather than blowing air out in a normal laminar flow system, it sucks air in. This proves useful, especially when working with hazardous materials. It prevents them from escaping the workstation.

Reverse Laminar Air Flow Working Principle

The Reverse Laminar Air Flow Working Principle is simple but effective. The system uses fans to pull air into the unit through a front opening. This air may contain dust, powders, or chemicals. Once the air enters the unit, it passes through special filters.

The most widely used filters are pre-filters and HEPA (High-Efficiency Particulate Air) filters. Pre-filters catch large particles. HEPA filters catch even the smallest particles and harmful chemicals.

After cleaning the air using the filters, the air is released into the external environment. This maintains the outer environment clean and free from impurities. The system operates continuously to have a clean and pure air environment.

So in plain language, the Reverse Laminar Air Flow operation is simply a process of sucking dirty air, filtering it through filters, and blowing clean air into the room.

Components of a Reverse Laminar Air Flow Unit

The following are the key components of a standard Reverse Laminar Air Flow unit:

Pre-Filter- Traps big particles such as fibers and dust before the air reaches the main filter.

HEPA Filter- This is the center of the system. It captures 99.97% of particles as tiny as 0.3 microns. Some of these include bacteria, spores, and other toxic particles.

Blower or Fan- Assists to draw the air into the unit and drive it through the filters.

Work Table or Surface- This is where the real work is performed, for instance, weighing powder or manipulating samples.

Lighting- Guarantees that the working environment is adequately lit for safe and accurate handling.

Control Panel- Provides a means of powering the unit on, inspecting airflow, and observing filter condition for the user.

Uses of Reverse Laminar Air Flow

Reverse Laminar Air Flow units are used in many industries and settings, including:

Pharmaceutical Industry- For weighing powder, use in handling chemicals, and in filling capsules.

Research Labs- For safeguarding the laboratory from biohazards or chemicals.

Hospitals- Where there is a need for sterilization or clean operations.

Food Industry- Against contamination in the packaging or handling of sensitive food.

Benefits of Reverse Laminar Air Flow

Safe guards the User

It safeguards the individual who is working with harmful substances from injury by pulling air away from them.

Prevents Contamination

Prevents dangerous particles from entering the room and being used to contaminate other products or equipment.

Lights Bad Air

The filter removes particles and dust that make the air bad.

Cost-Effective

Expensive, yes, but it saves health danger and product contamination, which can cost a lot in the long term.

Easy Maintenance

Most are easy to clean and come with replaceable filters.

Difference between Laminar and Reverse Laminar Air Flow

Laminar Air Flow blows pure air over the working surface to shield the product from external contamination.

Reverse Laminar Air Flow sucks in air from the front to shield the environment and user from dangerous materials handled on the working surface.

Both are applied in clean environments, but for different purposes. One shields the product, the other shields the individual.

Contact Reverse Laminar Air Flow Manufacturer

Reverse Laminar Air Flow is critical safety equipment in situations involving hazardous or delicate materials. It operates by sucking air into the equipment, purifying it, and releasing clean air to the room.

Having an awareness of the Reverse Laminar Air Flow Working Principle leads us to know why it is such a vital part in the pharma, healthcare, and research sectors. It not only protects the operator but also keeps the surrounding environment clean and secure.

With this system operational, businesses are more secure with security, with improved quality control and cleaner environments. This makes Reverse Laminar Air Flow a sheer necessity where contamination threats dominate. Contact Reverse laminar Air Flow manufacturers to get best quality clean room equipment.