Static Pass Box Manufacturer

Backed by expert professionals, we are known as the top static pass box manufacturer and suppliers in India. Our offered premium quality static pass box are used in many cleanroom operations that need precision, cleanliness, and contamination control. As a top static pass box manufacturer, we proudly offer cutting-edge limited area protection solutions. Our precision-engineered static pass boxes exceed industrial standards for smooth material transfer and sanitation.

Feel free to get in touch!

info@labswas.com

+91 97262 18377

Why Our Static Pass Boxes are Best?

Our static pass box design and production have earned us the reputation of best cleanroom static pass box manufacturer. Experience and innovation help us meet sterile and controlled sector needs. Modern technology and quality control ensure every static pass box we create meets ISO and cGMP standards.

Superior stainless steel (SS304 or SS316) makes our static pass boxes corrosion-resistant. Smooth, matt surfaces decrease particle build up and clean easily. Each client can tailor dimensions, interlocking mechanisms, and UV sterilization. Customized solutions that improve operating efficiency and cleanliness are our speciality. Our production policies prioritizes quality, reliability, and customer satisfaction.

Knowing Static Pass Box

Static pass boxes protect clean rooms with their advanced structure and design. A cleanroom or controlled environment’s static or passive pass box is sealed. It transfers materials between clean areas without impacting sterility. Employees should not enter or exit the cleanroom during material transfer to avoid cross-contamination.

Its robust interlocking door mechanism defines the static pass box. One entrance leads to the cleanroom and another to a clean area. These doors prohibit multiple openings with mechanical or electromagnetic interlocks. Air pressure and cleanliness are maintained by limiting direct airflow between the two locations. Opening the non-cleanroom door to load products locks the cleanroom door. After closing the first door, the second can be opened to remove items without polluting the cleanroom.

Static Pass Box Specification

| Model | SESP150 | SESP200 | SESP300 |

|---|---|---|---|

| Design type | Static / Passive | ||

| Internal Dimension (in mm) | 450L x 450W x 450H | 610L x 610W x 610H | 910L x 910W x 910H |

| Outer Dimension (in mm) | 570L x 510W x 590H | 730L x 670W x 750H | 1030L x 970W x 1050H |

| MOC | Stainless steel 304 | ||

| Illumination | LED tube light | ||

| Door | Two side doors Glass window SS handles & SS hinges Electromagnetic Interlocking system | ||

| Standard Fittings | UV light Light indicators for door SS Handles & SS hinges | ||

| Power supply | 220 Volts / 50 Hz | ||

| Optional | MOC SS 316 / 316 L Flange Test certificates Mechanical door interlocking Door buzzer UV light hour meter | ||

Static Pass Box Uses

Static pass boxes are used in industries where product quality and safety depend on cleanliness. They mainly used to transport goods between cleanrooms of the same cleanliness to preserve their integrity. Pharmaceutical manufacturers employ these adjustable devices to carry sterile tools, vials, and packing materials without contamination. Staff movement is limited by static pass boxes in GMP-compliant drug manufacture.

Static pass boxes are needed in biotechnology labs with fragile samples. They let researchers to transport samples, equipment, and consumables without microbial contamination. Static pass boxes protect fragile electronics components from dust and static electricity in electronics manufacturing. These equipments assist aircraft manufacturers assemble precise components in a clean environment for quality assurance.

Hospitals use static pass boxes to carry sterile supplies between operating rooms and prep rooms. Keeping surgical sites pathogen-free improves patient safety. Static pass boxes help research labs, chemical industries, and nanotechnology facilities maintain process purity.

Importance of Cleanroom Static Pass Box

Cleanrooms need static pass boxes since even the slightest particle or germ might cause problems. These devices are necessary for ISO cleanroom categorization, which is based on air particle count and size per cubic meter. Static pass boxes’ regulated transfer mechanism maintains airflow and pressure when cleanroom doors open.

Sterile settings are compatible with our cleanroom static pass boxes. High-grade stainless steel can withstand harsh cleaning solutions in cleanrooms. Seamless design prevents contamination and facilitates maintenance. Operators can check the pass box without opening the doors through tempered glass, reducing contamination.

Our static pass boxes offer door-open alarms and optional fire suppression for safety. Due to UV sterilization and interlocking, materials enter the cleanroom pathogen-free. For establishments with tight regulatory requirements, our pass boxes meet or exceed industry standards for peace of mind and operational reliability.

Dynamic Pass Box

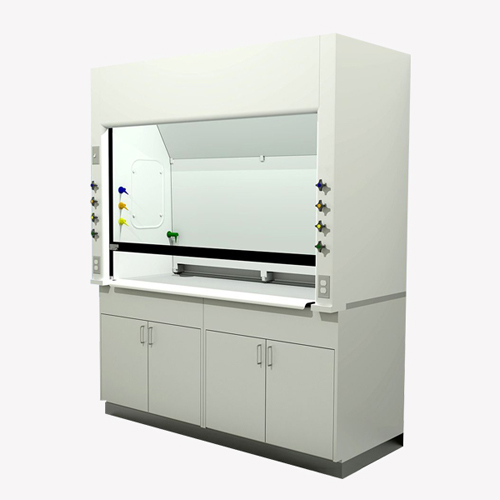

Fume Hood

Laboratory Fume Hood

Laminar Air Flow

Laminar Fume Hood

Modular Lab Furniture

Pass Box

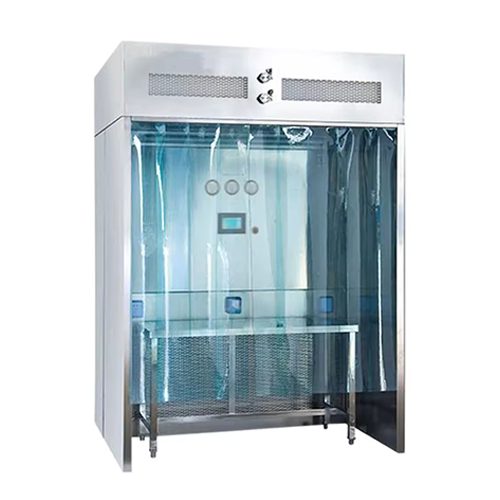

Sampling Booth

Static Pass Box

Vertical Laminar Air Flow

Horizontal Laminar Air Flow

Contact Best Static Pass Box Manufacturer

Contacting best static pass box manufacturer means choosing quality, reliability, and innovation. Our quality products maintain your laboratory clean and efficient. You can choose our static pass boxes:

- Pass boxes are made of high-grade SS304 or SS316 stainless steel to withstand cleanroom conditions and look clean.

- Our mechanical or electromagnetic interlocks prevent cross-contamination and maintain cleanroom integrity by opening only one door at a time.

- Customized Solutions: We develop to meet size, feature, and regulatory needs for seamless cleanroom integration.

- Pass boxes have UV sterilization, door-open alarms, and optional fire suppression systems to improve safety and contamination management.

- Global Support and Service: From installation to maintenance, our staff provides complete pass box support.

Our commitment goes beyond manufacturing. Installation, validation, and annual maintenance contracts keep your static pass box functioning smoothly. Many pharmaceutical, healthcare, chemical, food, R&D and biotechnology companies pick us for our global presence and on-time delivery.