What is Dispensing Booth?

A dispensing booth is also called a sampling booth or weighing booth. It is a unique clean air system popularly used in the pharmaceutical, chemical and food sectors. It has a unique design to safely handle powders or raw materials while weighing, mixing, transferring or sampling items. Additionally, it is also useful to handle granules and active pharmaceutical ingredients (APIs). One can easily find a dispensing both inside clean rooms where hygiene, safety and precision is most important. The booth keeps airborne particles from spreading so it protects the operator from breathing them in. Besides, the product stays free from contamination.

What Does It Look Like?

A dispensing booth is a stainless steel enclosure. It has:

● A front opening for easy access

● Transparent side panels for visibility

● Bright and no shadow lighting● Control panels to monitor airflow and filters

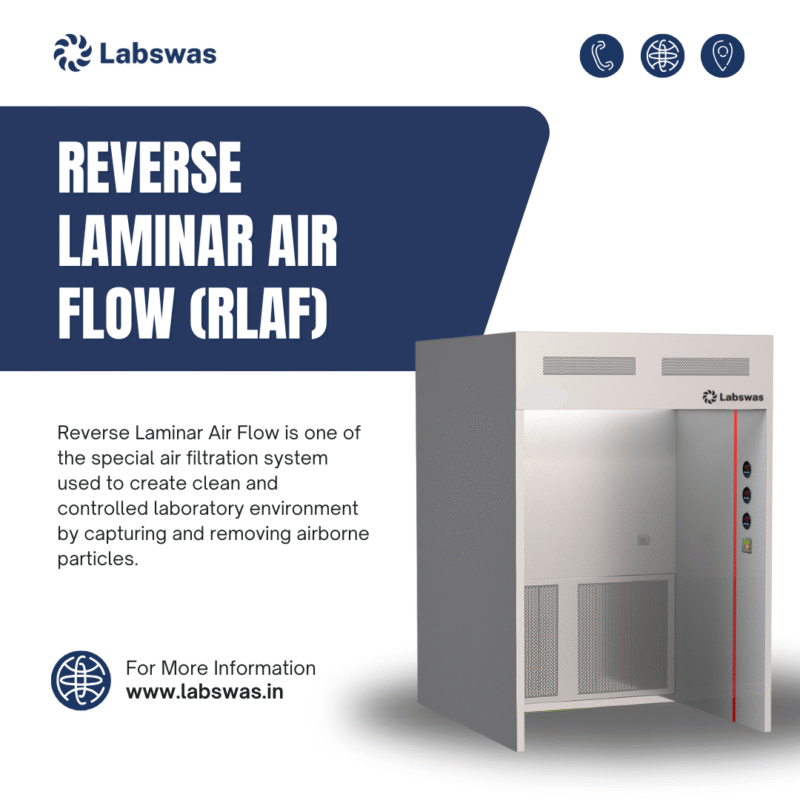

Role of Airflow in Dispensing Booth

What makes a dispensing booth effective is its air flow system. Clean air enters the booth from the top. It passes through HEPA filters. HEPA filters can trap 99.97% of dust, microbes, and tiny particles. Once filtered, the clean air flows downwards in a steady and vertical stream. This keeps the work area free from contamination. This type of movement is called laminar air flow. It plays a crucial role because it sweeps dust particles away from the breathing zone.

At the lower back or base of the booth, exhaust vents pull the contaminated air out. A portion of this air is filtered and recirculated. Where as the additional filters safely expels the rest. This constant movement of air creates a safe working environment inside the booth.

In some setups, the booth maintains negative pressure. Hence, it means air always flows into the booth, never out. This ensures that no contaminated air escapes into the surrounding cleanroom.

Why Is Dispensing Booth Important?

If you’re running a pharmaceutical facility, the dispensing booth is not a luxury but a necessity. We have mentioned the reasons below.

● For the operator: It reduces exposure to harmful powders and allergens.

● For the product: It keeps it safe from outside contaminants.

● For the process: It ensures batch after batch consistent quality.● For compliance: It helps meet GMP, WHO, US FDA, and EUGMP requirements.

Dispensing Booth Specifications

Dispensing booths aren’t one-size-fits-all. However, most booths used in pharmaceutical plants share some core specifications like these.

| Specification | Details |

| Construction Material | Stainless Steel SS304 / SS316 |

| Design Features | Smooth interior surfaces, minimal joints, transparent front/side panels |

| Air Flow Type | Vertical Laminar Air Flow (Recirculating or once-through) |

| Air Velocity | 90 ± 20 CFM (approx. 0.45 ± 0.05 m/s) |

| Filtration System | 3-stage filtration: Pre-filter, Fine filter, HEPA filter |

| Pre-Filter | Washable polyester fibers, 10 microns, arrestance 91% |

| Fine Filter | 5–10 microns, efficiency ~90–95% |

| HEPA Filter | 0.3 microns, 99.97% efficiency (H13/H14 grade) |

| HEPA Filter Brand | Labswas or equivalent |

| Noise Level | < 65 dBA |

| Light Intensity | 800–1000 Lux |

| Illumination | 1, 2, or 3 LED or Tube lights (based on size) |

| Power Supply | 220V ±10%, 50Hz, Single Phase |

| Blower Unit | Heavy-duty dynamically balanced motor blower assembly |

| Fittings & Switches | Main ON/OFF, Light ON/OFF, Blower ON/OFF switches |

| Optional Features | UV Light, Anti-static PVC Curtains, Magnehelic Gauge |

| Monitoring Devices | Magnehelic pressure gauge (for filter monitoring) |

| Validation Documents | Installation (IQ), function (OQ), and real-world performance (PQ) |

| DOP/PAO Test Ports | Provided for HEPA filter integrity testing |

| Warranty | 2 years standard warranty |

Dispensing Booth Design

The body is of stainless steel (SS304/SS316). The design includes vertical laminar airflow with three-stage filtration: pre-filter, fine filter, and HEPA filter. It has bright lighting (800–1000 lux), low noise (<65 dBA), anti-static PVC curtains. Moreover, it has simple control switches. One can easily find it in different size range from 3 to 6 feet wide. Smaller booths work great for basic sampling tasks, while larger ones are used for high-volume weighing and batch processing. Some models offer optional UV lights and pressure gauges.

Contact Dispensing Booth Manufacturer

A dispensing booth is one of the important cleanroom equipment. It helps in handling sensitive material without putting anyone or anything at risk. It keeps the air clean. Plus, it helps make sure the final product is top quality and keeps everyone safe. Many dispensing booth manufacturer offer best quality clean room equipment. They can also provide customize solutions for any type of application requirements. Get best quality dispensing booth.